Call us on+44 (0)1527 529809

News Update

10th January 2024

10th January 2024

First Aid updates….

Recently all of our staff (field and office alike) participated in mandatory first aid training.

The course undertaken provided our staff with a comprehensive set of practical skills needed by first aiders, giving them both the ability and knowledge to deal with first aid emergencies.

The day consisted of several practical assessments, including a scored CPR session on a dummy!

Overall staff found the session informative and engaging.

7th July 2023

7th July 2023

SPE Ltd goes digital….

In the early days of SPE, we operated on a largely paper-based system which, at times, could be cumbersome. We had been researching and working towards installing a digital system, however Covid-19 forced our hand to make the decision sooner than expected; we swiftly moved to a paperless, digital way of working and have not looked back since.

To further improve our systems and services, we have recently invested in and implemented the ‘Big Change’ job management platform.

The Big Change system boasts a range of powerful/business critical functions in one user-friendly platform, including:

• Customer Relationship Management

• Job Scheduling & Live Tracking

• Field Resource Management

• Financial Management

• Business Intelligence

For SPE, the biggest benefit is the visibility that it gives our office and field teams. All the information we need is instantly available so we can manage everything with a more dynamic approach, whilst also improving communications with our clients. Our future depends on both the quality of work and the quality of service that we deliver today – and Big Change gives us the tools we need to deliver on our promises.

12th August 2022

12th August 2022

Another new contract awarded!

We are proud to announce that we have been awarded another major contract, this time with a fuel supply group. The contract consists of the provision of planned preventative maintenance and reactive maintenance to pump stations, sewage treatment plants and any drainage equipment on 47 sites across the UK; a very exciting opportunity that has developed from a pre-existing service schedule with our customer.

The expansion of responsibility not only showcases SPE’s commitment to our customer base but also evidences the high standard of work we provide.

Business Development Manager, Paul Muckle, said “SPE sets the pace with yet another new contract! What a great expansion to an already existing customer relationship”.

24th February 2022

24th February 2022

Village-sized new STP project completed!

SPE Ltd has just completed a major project at Wood Norton, on the outskirts of Evesham in Worcestershire. The project, undertaken jointly for The Wood Norton Hotel and the Bupa’s recently built Richmond Care Village, has taken over 12 months to complete and included the design, build and final commissioning of a new sewage treatment plant (STP) and a reed bed that will be planted out when the threat of frost has passed.

Due to its age and size, the original STP which serviced both properties needed replacing so SPE Ltd, in consultation with the Environment Agency, drew up a design that would not only cope with the current loads and flows from the properties, but also future-proofed the plant by allowing for the advised additional development which is planned for both sites. The new plant was designed and specified to be an above-ground system installed on the Hotel’s raised, disused tennis courts, as a safeguard to possible flooding from a nearby river.

SPE Ltd applied for and were granted a new Permit to Discharge from the Environment Agency. SPE Ltd also gained planning permission from Wychavon and Malvern Hills District Councils Planning department, however there was one small glitch in the initial planning stages; the new system had to allow for a footpath to be reinstated across the tennis courts – which had not been accessible for over 40 years! After discussions with Worcestershire’s Public Rights of Way, diversion notices were applied for and issued, allowing the official closure of the footpath until the development was completed.

Tom French, the Capital Projects & Refurbishments Manager for Bupa Care Services said: “SPE had provided both planned and reactive maintenance for our system previously and always to a high standard of both work and service. Subsequently an upgrade was identified as a requirement which SPE explained and offered their services to provide.

SPE took control of the entire process, they managed the design, the procurement, the installation and the handover in addition to liaising with the Environment Agency. The level of faith and assurance I have in SPE throughout this process is second to none, the knowledge and personable service they offer couldn’t be higher. SPE also go the extra mile, this involved liaising with the residents and operatives within Richmond Village including numerous site tours and detailed handover, in addition to unknowns occurring during the process. Despite the fact the installation has been handed over, SPE are still present ensuring the system is working to its optimum level in the initial weeks and I could not be more comfortable in the fact that they will continue to maintain it going forward.

They provide a transparent service and are always available to resolve queries or issues that you as the client may be encountering during the process (of which I can happily say were extremely few and far between). I wouldn’t hesitate to recommend SPE for both maintenance and installation appointments.

The service from site level to the office they provide is swift, professional and an extremely personable service – an incredibly enjoyable organisation to work with.”

The local Environment Agency Officer visited site after the hand-over and carried out sample testing on the final effluent – which fell well within the levels of consent laid out in the new Permit to Discharge. Needless to say, Bupa, The Wood Norton Hotel, SPE Ltd and the Environmental Agency are all over the moon with these results, considering the plant had only been up and running for a week!

Operations Director appointed.

Congratulations to Matt Hawkes who was recently appointed Operations Director of SPE Ltd. Matt has been with the company since he was a mere lad and has helped SPE grow and develop into what it has become today.

“I am truly honoured to become a Director of SPE. Since joining the company over 16 years ago I have been fortunate to learn and develop my personal skillset whilst having the opportunity to be heavily involved with company development” said Matt, continuing “as newly appointed Operations Director, I would like to thank Richard, Ruth and team. My focus will remain to deliver the highest levels of service at all levels within the business with a committed approach.”

Well done Matt – you more than deserve it.

Awarded contract for Essex Police, Fire and Crime

Recently SPE’s admin team has successfully tendered for and won a 3 year contract for the pre-planned maintenance of Essex Police, Fire and Crime’s Deep Lifts Pits, Interceptors and Foul Water Disposal Plants across over 30 sites.

The tendering process was marked on both price and quality, with SPE taking the lead out of 5 companies within our industry. This win not only showcases SPE’s commitment to fair and competitive pricing but also our ongoing commitment to high quality standards, further aided by our ISO 9001 & ISO 14001 accreditations.

We are incredibly proud of our team’s success in winning the contract and would like to thank them for all the hard work that they put into the application process. We look forward to winning many more….!

ISO 14001 : 2015

ISO 14001 : 2015

May 2021- We are pleased to confirm that SPE Limited has achieved ISO 14001:2015 accreditation.

ISO 14000 is a family of standards related to environmental management that exists to help organisations minimise how their operations negatively affect the environment; comply with applicable laws, regulations, and other environmentally oriented requirements; and continually improve in the above.

Our ISO management system standard helps us to improve our performance by specifying repeatable steps that we consciously implement to achieve our goals and objectives, and create an organisational culture that reflexively engages in a continuous cycle of self-evaluation, correction and improvement of operations and processes through heightened employee awareness and management leadership and commitment.

The benefits of our effective ISO14001 management system includes:

• More efficient use of resources and improved financial performance

• Improved risk management and protection of people and the environment

• Increased capability to deliver consistent and improved services and products, thereby increasing value to customers and all other stakeholders.

Click here to view/download a copy of the certificate.

6th November 2020

Major refurbishment project completed

Major refurbishment project completed

SPE Ltd are proud to announce the completion of a major project, the refurbishment of a sewage treatment plant for a large and exclusive 5-Star Hotel, Spa and Golf Course on Dartmoor National Park.

The upgraded treatment plant had to be designed to fit within the constraints of an existing compound area and there were major access issues, due to both the narrow Devon lanes and two low, arched, stone gateways on the property that had to be navigated for deliveries of plant and machinery. These made life very interesting when delivering the three 12.5m tanks and control kiosk, not to mention the concrete mixers…!

Richard Smith, MD of SPE Ltd commented “it was an interesting and exciting project to undertake, involving a lot of planning and organising to ensure it all came together. One pretty major issue we had to overcome was caused by the COVID-19 lockdown. Many of the site visits were undertaken during March to June when the roads were very quiet which was a bonus, however sourcing the supply of some products was difficult, as was communications at times, due to home working, furlough and company shut-downs. I am pleased to say that our suppliers and contractors worked very hard for us to ensure that we could complete the project on time and within budget.”

Our very happy client stated: “If you ever wanted a true example of how a turnkey project should be run, this is that example. SPE took ownership from day one and proactively kept my client and myself in the loop from start to finish. Five star service and delivery.”

The project, one of the largest that SPE has undertaken, included the design, specification, installation and commissioning of the system and has taken around 12 months to carry out, from the initial site visit to the final hand-over of the completed project.

9th July 2020

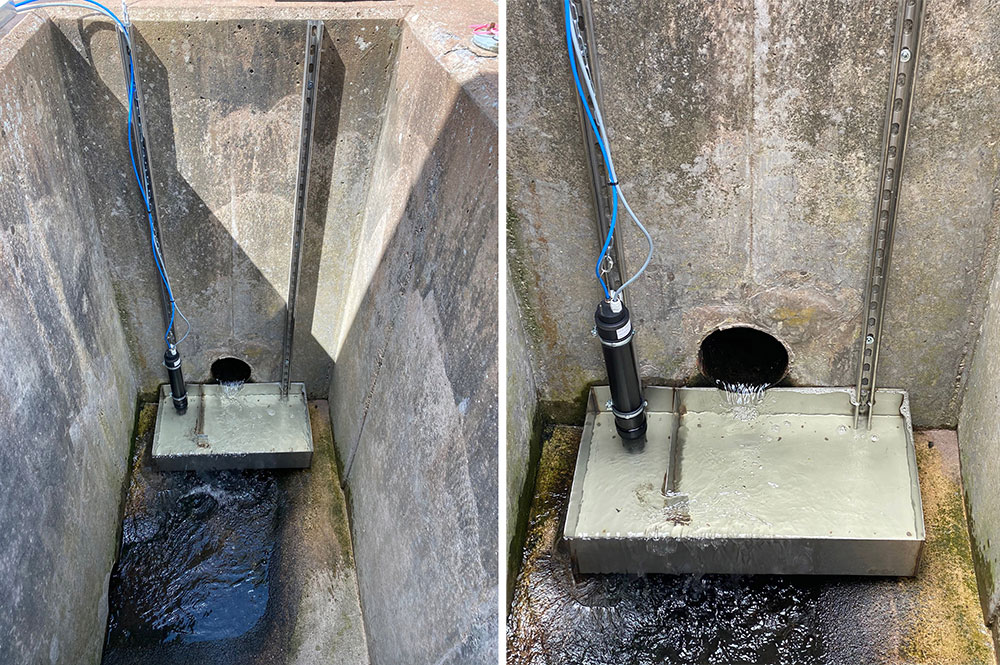

Custom-designed Ammonia Monitoring System

Custom-designed Ammonia Monitoring System

SPE recently installed a new ammonia monitoring system at a wastewater treatment works within the UK.

The site already had a system in place that monitored the levels of ammonia contained within the effluent being discharged from the site. The old system had proved very reliable, however after many years of service it was due to be retired.

The replacement system specified by the client comprised of a new probe assembly that differed in size from its predecessor and this posed an issue with the install. The previous system was designed to work in conjunction with the relatively large range of operation within a wet well. The new probe had a much shorter body, which meant that the large range of pump operation within the wet well posed the risk of full submersion.

Both SPE and the client worked out a method of installation that would eliminate the risk, involving designing and fabricating a stainless-steel catchment tank, and installing the probe and tank in a new location.

SPE commissioned local company B Hepworth & Co Ltd, to fabricate the catchment tank from 316 stainless steel. The design incorporated support / runners to locate the probe securely and an integrated baffle. The catchment tank has some rather sexy looking welds (if you’re into that kind of thing!) and should stand the test of time, given the quality of the materials and workmanship.

The design and installation work perfectly and the new probe looks completely at home as it measures the levels of ammonia within the effluent leaving the site…and we have one very happy client!

18th June 2020

Shock loading? A Reed Bed may be the answer…

Shock loading? A Reed Bed may be the answer…

An outward bound centre in mid-Wales had a sewage treatment plant that processed the waste water from site, but it was suffering with various issues caused by shock loading.

We initially carried out remedial works to help manage the problems and to better control the shock loading, however despite obtaining good test results from the treatment plant, due to the tight enforcement levels on the Consent to Discharge further tertiary treatment was required.

SPE analysed all the flow data and available information in order to design and install a polishing plant in the form of a Reed Bed. This particular system has proved time and time again to have an extremely positive effect on the quality of discharge from systems such as this.

The Reed Bed is now ready for reed planting, which will be carried out once the site reopens for business – something that we hope happens very soon! Once the reeds establish themselves, we expect to see a high standard of discharge.

The site’s General Manager commented: “SPE’s Operations Manager, Matt Hawkes, met us on site on the first day and the contractors were very professional. Health and Safety was at a high standard and work commenced quickly. The time frame was 5-6 days and they had the project completed on the morning of the 5th day. It is early days but we are hopeful that this installation is going to solve our previous problems. We look forward to working with SPE in the future and appreciate the effort they have put in to solving our problems”.

Click here for more information on reed beds, or contact us if you have a requirement – we are happy to help!

December 2019

New project completion

We have recently completed a major Sewage Treatment Plant installation project in Herefordshire, which included consultancy, overseeing the tender process, project management and final commissioning.

The conditions for the installation were appalling considering the extremely wet weather that we have experienced in the last couple of month of 2019. Our engineers gained in height as their boots grew muddy platforms, and the washing pile for Hi-Vis back in the workshop was never ending!

However we are delighted to say that the project was successfully completed and commissioned in time for Christmas.

July 2019

Septic Tank and Sewage Treatment Plant Regulations 2020

In January 2015, new rules were introduced that simplify the way septic tanks and small sewage treatment plants are regulated in England, protecting the environment and improving water quality.

If you have a septic tank that discharges directly to a surface water you will need to replace or upgrade your treatment system by 1 January 2020. Where properties with septic tanks that discharge directly to water courses are sold before 1 January 2020, responsibility for the replacement or upgrade of the existing treatment system should be addressed between the buyer and seller as a condition of sale.

If the Environment Agency finds evidence that your septic tank discharging to a surface water is causing pollution, you will need to replace or upgrade your system earlier than 1 January 2020. You will usually have to do this within 1 year, although this will be agreed on a case-by-case basis.

If you have a septic tank or small sewage treatment plant

As the ‘operator’ of a septic tank or small sewage treatment plant you must check you meet the general binding rules. You must apply for a permit if you do not. You’re an operator if any of the following is true:

• you own the property that uses the system

• you own a property that shares the system with other properties – each property owner is an operator, and you’re jointly responsible for complying with the general binding rules

• you have a written agreement with the property owner that says you’re responsible for the system’s maintenance, for example you’re renting and it’s in your tenancy agreement

Use the correct treatment system

You must use a small sewage treatment plant to treat the sewage if you’re discharging to a surface water such as a river or stream. A small sewage treatment plant (also known as a package treatment plant) uses mechanical parts to treat the liquid so it’s clean enough to go into a river or stream. Discharges from septic tanks directly to a surface water are not allowed under the general binding rules.

How SPE can help

SPE can specify and supply Sewage Treatment Plants to cater for 6 population equivalent to 150+ population equivalent and offer a Project Management Service to design and oversee the installation if required. Our Sewage Treatment Plants are specified for minimum low-cost maintenance and, as independent specialists, we will specify the system that best meets the requirements of each individual application. We offer a full commissioning and after sales service, including individually tailored Maintenance Contracts involving planned maintenance visits.

Click here to download Environment Agency guidance on regulation of septic tanks and small sewage treatment plants: important information for households and businesses with septic tanks and small sewage treatment plants.

Click here for more information from the Environment Agency.

March 2019

One-stop drainage stop!

A client recently requested that we become a one-stop shop for all of their drainage requirements, so we felt that a bit of investment was needed…

The vans have been equipped with a whole bunch of new goodies to ensure that we can carry out the additional work this will bring in, including a Drain Inspection Camera.

“The lads have all been trained in the use of the new equipment and are enjoying their rats-eye view of what is going on underground” remarked Richard Smith, MD. “It has already assisted with diagnosing faulty and problems that the client was previously unaware of.”

March 2019

Care Home contract extended

We are proud to announce that the contract we were awarded nearly 12 months ago, for the maintenance and repairs to various sewage treatment plants and pumping stations at 26 Care Homes in the Midlands and South East, has been renewed for another 3 years.

“We are thrilled to have been awarded the extended contract” said Matt Hawkes, SPE’s Operations Manager. “It has been an exciting opportunity and has certainly kept us on our toes over the last 12 months. We have assessed the specific needs of each of the client’s sites during the first 12 months and advised accordingly. It is very satisfying have such good two-way communications with a client; our proposals have been welcomed and are proving to have reduced costs, improved reliability and minimised down-time.”

We are looking forward to continuing building our close working relationship with the client.

March 2019

Consultancy and refurbishment

A rural cafe and farm shop with a booming business approached us for help, as their plant was struggling to comply with strict EA guidelines. The business was thriving and the huge increase in footfall – they were doing 600 covers a day at peak times – had massively increased the loadings on their sewage treatment plant.

We analysed the site data and designed an upgrade to the existing treatment plant, which included a larger grease trap, plus replacement and additional equipment to improve the oxygenation in the existing biological process. We also installed a 15m x 6m reed bed which will help with the final purification of the effluent and a sample chamber was installed for ease of future sampling.

We are pleased to announce that recent samples taken have been analysed and they are well within consent limits. Best of all, we have one happy client!

February 2019

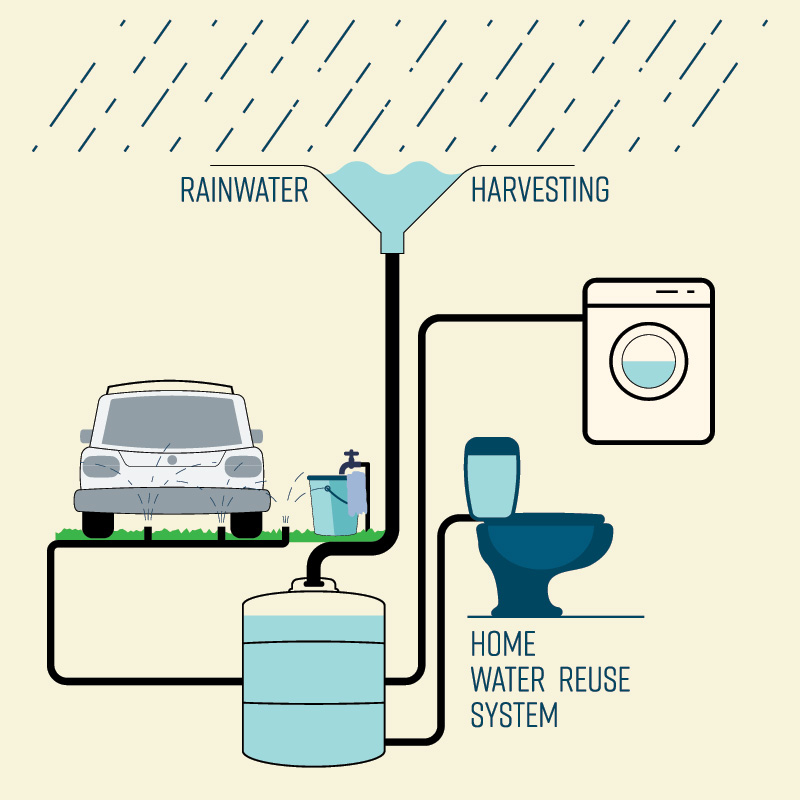

Grey Water Harvesting contract

We have been awarded a three year contract for the repairs and maintenance to grey water harvesting / recycling systems for 19 social housing sites in the North West.

Peter Bridgewater, Business Development Manager for SPE stated “We tendered for this contract in late 2018 and were delighted to be awarded it in February this year, commencing in April.” Peter continued “We have installed and maintained many grey water recycling systems across the country, from garden irrigation systems, to commercial installations in major UK cities. It is interesting work and we greatly enjoy being involved with these types of projects”

August 2018

Business is booming…..

SPE has recently landed a new contract for the servicing and maintenance of the pumping stations belonging to a chain of Care Homes, the majority of which are based around the London region.

MD Richard Smith commented “Most of the pumping stations proved to be in a very poor state of repair so, together with our client, we will be implementing a strategy to bring them all back up to optimum operational condition as a matter of urgency”.

SPE’s new Business Development Manager, Peter Bridgewater, has hit the ground running too, landing contracts with a major hotel chain with branches throughout the country, and also one of the UK’s leading environmental solutions companies.

August 2018

Staff news

Staff news

We would like to congratulate Matt Hawkes on his promotion to Operations Manager. Matt is taking on more and more of the planning and organisation of the business, especially when it comes to the larger, more complex projects that we are involved in.

Matt has been with SPE since 2005, joining us as an electrical apprentice and gaining his City and Guilds in Electrotechnical Technology Installation. He worked his way up to Senior Engineer before this most recent promotion, and is also a shareholder in the business.

We would also like to congratulate Lewis Taylor on his recent promotion to Engineer.

August 2018

Trickle Filter refurbishment

Trickle Filter refurbishment

SPE has recently completed the refurbishment of another trickling filter serving a manor house outside Milton Keynes.

The system had seen better days when we were initially called to site. SPE carried out a full refurbishment including having new parts machined to our design.

The system is now working very well and we have another happy customer.

If you would like to know more about how these systems work and what we can offer please contact us here at SPE.

August 2018

London’s Five Billion Pound ‘Super Sewer’

London’s Five Billion Pound ‘Super Sewer’

Around 39 million tonnes of raw sewage overflows into the River Thames in London each year, so a new 20 mile long super sewer is being built to clean up the Thames and help accommodate the capital’s growing population.

BBC Two has commissioned a three-part documentary series following the £5bn project following workers across London as they race to build London’s 20 mile-long ‘super sewer’, cutting through the heart of the capital deep below the Thames.

The Five Billion Pound Super Sewer is part mega-engineering, part specialist factual exploration of London’s rich and dirty history. Filmed over three years, the series charts the progress and setbacks faced by a team of 4000 construction workers tasked with creating London’s deepest ever tunnel – directly beneath the river Thames. It also delves into the subterranean world to explore the state of the city’s ageing sewer network.

Building the super sewer is the biggest infrastructure project ever attempted by the UK water industry, designed to intercept sewage that currently floods out of the overstretched Victorian system and into the Thames – each year, almost 40 million tons of sewage has to be discharged directly into the river.

An amazing feat of engineering, catch up with it now on BBC2 IPlayer. Click here for more information. Picture courtesy of the BBC website.

July 2018

SPE Limited achieve ISO 9001:2015 Accreditation

SPE Limited achieve ISO 9001:2015 Accreditation

SPE are very proud to announce that they have achieved ISO 9001 accreditation within a matter of weeks! The initial assessment was on 22nd May 2018, with the certificate being awarded on 18th July 2018.

In order to continue with the ongoing growth and development of the business, the company decided that a lot of the internal business processes needed to be formalised, providing improved internal communications and help focusing on the important areas of the business. The aim was for management processes to be established throughout the business, providing a sound foundation and leading to increased productivity and profit through improved efficiency and communications.

Worcester-based ISO Quality Services Ltd (ISOQSL) was selected as the company to help SPE through the process. During the initial assessment it was shown that SPE already had most of the required processes in place; recommendations were made by ISOQSL of additional processes which needed to be implemented in order to achieve accreditation.

“Working with Richard, Ruth, and their team through the process of gaining the ISO 9001:2015 was a pleasure. They were easy to work with and showed full commitment to the process” said Colin Watkins, Senior Lead Assessor for ISOQSL. He continued: “they embraced all the recommendations given to them and we can already see a difference in the business in this short period of time. They were responsive and communicative throughout, and we look forward to our future visits with them.”

All of SPE’s staff are aware of the systems now in place and have fully embraced the move, knowing that it is of benefit to everyone within the company. Surprisingly, it doesn’t mean that much more paperwork is involved, just that the information is handled more efficiently.

Richard Smith, Managing Director of SPE Ltd stated “I can highly recommend ISO Quality Services Ltd and, in particular, Colin Watkins and Chrissy Bligh. They made what initially appeared to be an arduous, complicated process easy to understand and very beneficial to our company. We are already reaping the rewards and we have only just been certified!”

Pictured left to right: Steve Lees (SPE, ISO Admin), Colin Watkins (ISOQSL, Senior Lead Assessor), Chrissy Bligh (ISOQSL, Client Services Account Manager) and Richard Smith (SPE, Managing Director).

Cick here to view / download a copy of the ISO Certification. Click here for further information on ISO Quality Services Ltd.

June 2018

SPE gaining ISO 9001 Accreditation

We are pleased to confirm that SPE Limited is undergoing the implementation and accreditation for the ISO 9001 : 2015 Management Standard, and we anticipate certification within the next two months.

ISO 9001 : What is it?

A Quality Management System is a systematic and process driven approach to managing the business. It is designed to support the company in ensuring that they meet and exceed the needs of their customers, whilst delivering a consistent level of quality and satisfaction.

Watch this space….!

January 2018

Stately Home’s rotating biological filter refurb……

SPE has recently completed the refurbishment on the Treatment Plant belonging to a Stately home on the outskirts of Bristol.

The first phase of the work consisted of resealing settlement tanks and chambers with butyl liners and some electrical control work. The remaining phase was to refurbish the rotating biological filter mechanism and bring the plant back up to full working order. This work was completed at the beginning of January, is working well – and looks very pretty if we do say so ourselves!

November 2017

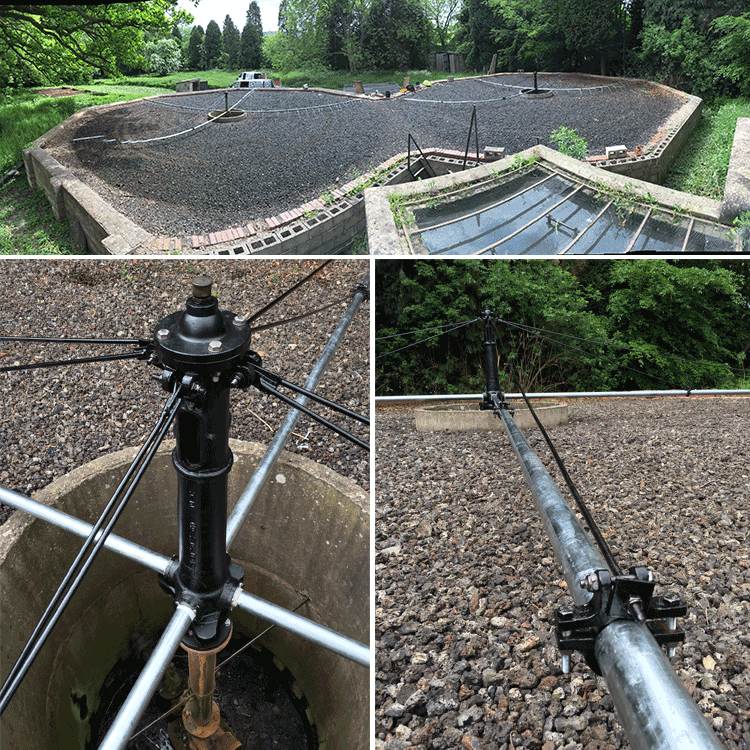

Completion of WW2 Filter refurbishment

SPE has completed the refurbishment a Rotating Biological Filter dating back to World War II.

The filter shown is one of two, both of which are part of a sewage treatment works in Blockley, Moreton-In-Marsh. The system was originally built to serve a hospital during the war and after 1948-1965 became the largest Polish Refugee camp in the country. The site is now used as a business park.

This project was started back in June 2016, with SPE stripping, re-engineering and re-assembling the rotating assembly for one of the filter beds, which had seized; several of the arms had corroded and collapsed.

This year, we completed the project by refurbishing the rotating assembly on the second bed and commissioning the system back into full operation. SPE called upon their years of expertise and understanding to design and manufacture the parts required for the rebuild. In conjunction with a local precision machiners, we were able to produce the replacement components required for the rebuild.

The system has been running problem free since the refurbishment of the first filter bed in 2016, with it being maintained by SPE on a monthly basis ever since. Now the second system has been fully restored we look forward to seeing the complete system continue to run for many years to come.

August 2017

Ka-BOOM!!!

We were called to see a prospective customer who wanted to take out a Service and Maintenance contract with us. Upon arriving and inspecting his installation, we were horrified to see that the control panel had been sited INSIDE the tank……

Not only didn’t the installation comply with DSEAR’s, (The Dangerous Substances and Explosive Atmospheres Regulations 2002) but a whole host of other regulations too!

Imagine the gases that build up inside these tanks from what is put into them…..and then imagine a spark inside the control panel when one of the pumps kicks in. Like the title says – Ka-BOOM! The mess doesn’t bear thinking about 😉

August 2017

“Flushable” Wipes can seriously damage your pumps!

Two large and expensive burned out pumps illustrated to one of our clients recently the importance of not flushing “Flushable” wipes down the toilet. These wipes DO NOT disintegrate in the same way that toilet roll is designed to do, and so will build up and cause blockages.

It was cheaper and quicker to simply replace the pumps rather than remove them for repairs, which took a week as the pumps had to be shipped in from overseas. Meanwhile a tanker had to be called in on a daily basis as the installation could not be shut down.

An expensive lesson to learn, so take note all you wipes users…..!

May 2017

Compliments on our installation

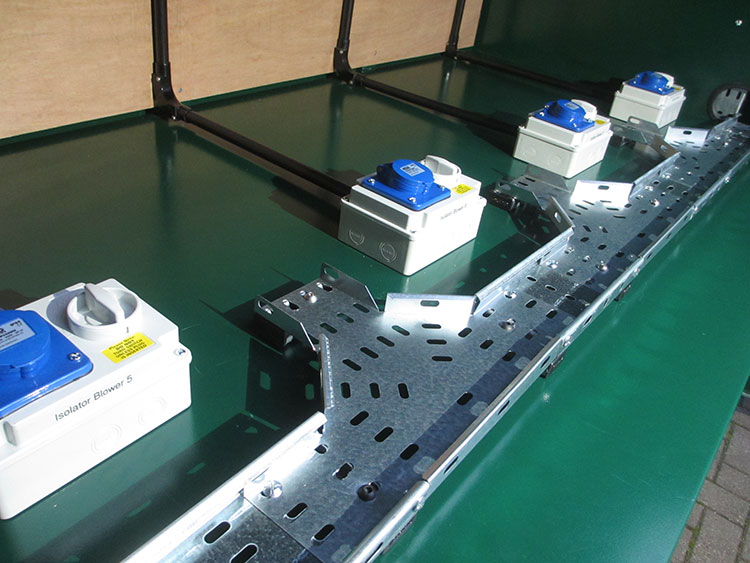

One of our suppliers was so impressed with a recent installation we undertook using their products, that they have featured it on their website as a “textbook installation”.

They say: “We don’t often get to see where and how our Secoh pumps are installed, but a recent project displaying an in depth understanding of the product caught our attention……”

Thanks Bibus!

Click here to go to the full article.

May 2017

Stately STP brought up to date

A stately home on the outskirts of Bristol had been converted into apartments and the original sewage treatment plant, which was sited in the middle of a neighbouring landowner’s field, was failing.

SPE was called in to consult and make proposals for remedial works required to bring the plant back into working order and, upon our recommendations, we were awarded the order. The work carried out included resealing the primary settlement tank and syphon chamber with butyl liners.

Also, the syphon in the syphon chamber had rusted to pieces and, as there was no access to an electrical supply on the site, we installed a solar panel and battery back-up system which would run a pump, dosing the filter bed with effluent.

The plant’s outfall is now being monitored on a regular basis, with samples being sent to the Environment Agency for analysis.

May 2017

A dodgy control panel can damage your pumps…

A client whom we had been advising for over 12 months to upgrade a defective control panel, called us 2 days before a Bank Holiday weekend to say that his system had failed.

When we attended site we found that both pumps had been running continuously due to the faulty panel and, as a consequence, both pumps had burnt out.

Instead of just replacing the panel, we had to also replace two large and expensive pumps, plus the client had to cover tankering costs until the new pumps were delivered and could be installed.

May 2017

Telehandler solves weighty problem

An out-of-town shopping centre in Stratford-upon-Avon was having problems with its storm water pumping system. Upon inspection, we found that one of the pumps had failed, and the other was on the way out.

We also found safety issues with the control panel which needed to be addressed as a matter of urgency.

We considered and quoted for several options, including repairing the pumps and panel, but the client favoured a complete replacement and upgrade to two new pumps, a new control panel and new switchgear. The job needed quite a bit of planning as it involved shutting off an area of public car parking, plus the requirement of a telehandler to lift, remove and replace the pumps, each of which weighted 350kg.

End result: one working, safe pumping station, one happy client!

February 2017

Care Home RBC problem solved within tight budget!

SPE was called in to advise on what could be done about an old RBC (Rotating Biological Contactor, aka Sewage Treatment Plant Disc Unit), which was not working. The treatment plant serviced a Midlands-based charity-financed care home which did not have a budget large enough to cover a replacement plant, which they had been advised they needed.

Upon inspection, SPE found that the plant was not big enough to cater for the premises, whose requirements had grown over the years. SPE were able to offer a remedial solution that they felt would work, which included replacing the rotating shaft in the plant, and installing media and air blowers to help with efficiency.

The plant is now under a regular maintenance contract, visited on a quarterly basis and is meeting the required standards.

“This was an interesting project” said Richard Smith, MD of SPE Ltd. “We were very aware of the budget restraints and so researched a variety of avenues in order to find the best and most cost-effective long-term solution for the client. New is not always better!”

November 2016

Hinkley Point C Contract completed and handed over

The work on the Hinkley Point C Nuclear Power Station sewage treatment plant and pumping station has now been completed, commissioned and handed over. This treatment plant has been installed as a temporary measure, to service the newly-built offices for the construction staff.

The work included the design and fit of a large electrical control kiosk, the supply, fit and wiring up of pumps, blowers and UV filters plus all the control systems, the design and installation of a sampling point and finally the writing and supply of the O&M Manual.

“This job was undertaken over a very short period of time, especially considering the size of the project. Working on Nuclear Power Stations requires a high level of workplace professionalism and in-depth knowledge of EDF procedures, and I am proud to say that our team of Engineers have delivered a first rate piece of work” said Richard Smith, SPE’s MD.

October 2016

SPE awarded Hinkley C Contract!

SPE Limited has been awarded a contract at the Hinkley C Power Station build site.

As an independent specialist company offering nationwide coverage for sewage pumps, sewage treatment plants and dirty water pumping stations, SPE Limited has been contracted to complete the installation and commissioning of a 150 person sewage treatment plant and pumping station, which will service the offices and various contracting agencies during the build of the new Nuclear Power Plant.

The work will take a month to complete and includes the design and fit of a large electrical control kiosk, the supply and wiring up of pumps and UV filters plus the necessary control systems.

Richard Smith, SPE’s Managing Director said: “We were delighted to be awarded the contract, which is due for completion by the end of October. We have been working with various power stations for the last 10-15 years, including Hinkley B and so have a great understanding on the quality and the levels of workmanship expected for this type of project”.

September 2016

…where do you NOT fit solar panels….?

SPE was called out by a new client to investigate an installation in Kent, where an oil interceptor alarm was not working.

Part of the installation included a battery driven alarm which was wired up to be recharged by a solar panel. Upon testing, we found that the battery was flat….possibly due to the solar panel being sited in the shade, underneath a bridge!

The client requested that we fit an entire new system, including re-siting the solar panel where it would charge correctly in future.

The system has been working well for some time now, as has a 2nd system that the same client asked us to check over and which turned out to have exactly the same fault. We have gained another happy client.

June 2016

WW2 Filter receives some TLC

SPE has refurbished a Rotating Biological Filter dating back to World War II.

Wastewater from the primary settlement tank is continuously sprayed over the filter and organics within the water are aerobically degraded by the biofilm on the filter media.

The filter shown is one of two, both of which are part of a sewage treatment works in Blockley, Moreton-In-Marsh. The system was originally built to serve a hospital during the war and after 1948-1965 became the largest Polish Refugee camp in the country. The site is now used as a business park.

The rotating assembly had seized and several arms has corroded and collapsed. Knowing that parts for this system had gone out of production years ago, SPE confidently grasped the opportunity to demonstrate their abilities when it comes to refurbishing. Where others would simply walk away or quote on a replacement system, SPE called upon their years of expertise and understanding to design and manufacture the parts required for the rebuild. In conjunction with a local precision machiners, we were able to produce the replacement components required for the rebuild.

With minimum downtime, SPE successfully stripped, re-engineered, re-assembled and commissioned the system back into full operation. The system has since been running problem free and, with it now being maintained by SPE on a monthly basis, we look forward to seeing the system continue to run for many years to come.

© 2025 SPE Ltd | Privacy Policy | Quality Policy | Environmental Policy | Designed by SPE Ltd